Rinse, wash, repeat – developing replicable solutions to make washing artisanal cobalt safe and fair

The FCA is determined to support the adoption of better health and safety practices in artisanal cobalt mine sites. Starting April this year, the washerwomen at the Kamilombe mine site, a partner mine of the FCA run by the cooperative CMDS, the women have been able to gain access to wader boots on a daily-hire basis to protect their feet when washing cobalt in water. A launch ceremony was held to launch the Personal Protective Equipment (PPE), and the project recipients have since benefited from more decent working conditions, ecstatic about managing their health concerns.

Mineral washing at artisanal cobalt mine sites

In the artisanal cobalt sector, women are primarily responsible for washing the cobalt ore – an activity done to increase the ore’s purity and increase its selling price. Locally known as lavages, the women washers identify and clean rocks that contain the most ore through visual judgement and thus increase the cobalt grade for each bag. Women in this sector are also actively involved in the provision of other auxiliary services that support mining communities, such as the provision of food and the selling of clothes.

In Kamilombe, an estimated 650 women work at the Coopérative Minière pour le Développement et le Social (CMDS) mine site that has partnered with the FCA. Ore washing is one of the lower-paying tasks, with an average pay of $2.50 per 25 kg bag, with one woman estimated to wash between 3 to 5 bags daily. Recently, women washers in Kamilombe have organised into an association, registering formally and issuing photo IDs to prove their membership.

Health and safety concerns: why the current practice persists

Although it has been happening for decades, ore washing in water without PPE subjects miners to a variety of operational health and safety risks. These include skin rashes and infections from exposure to heavy metals in the dirty water. Washers usually stand directly in washing ponds using neither gloves nor boots – rinsing off any dirt in the ore by repeatedly lifting a metal net or a plastic bag lightly filled with ore using their bare feet. Health risks are notably reduced when washers have the chance to wash in rivers where there is free-flowing water, or when the water is replaced regularly.

Women involved in this work have long complained about its related risks. An obvious yet not easily adapted solution is to use personal protective equipment (PPE). The current lack of adoption of PPE use lies in the unavailability of the gear locally. Where available, total upfront costs have proven too expensive for the women.

One of the FCA’s core objectives is to facilitate the transition toward safe and dignified working conditions for artisanal miners. The problems around washing cobalt provide a real opportunity to create a direct and lasting impact, by improving the working conditions for 650 women in Kamilombe.

Washerwomen work long days in hazardous conditions. The longer and harder they work, the more they can earn, but the more they are exposed to unhealthy conditions.

Providing safe and dignified working conditions

On April 18th this year, a PPE distribution project was ceremonially launched by the FCA and CMDS. Executed by CMDS and the washerwomen’s association at the Kamilombe mine site, the project objective is to help local washerwomen operate safely without any risks to their health. In preparation, the FCA provided support by interviewing all stakeholders involved to define the most appropriate PPE and, having identified wader boots as the preferred PPE option, the FCA facilitated the import of over 600 units.

The FCA also helped develop a detailed procedure describing the management setup for the daily-hire provision of wader boots, training the management team of five hired by CMDS, and supporting the preparation of the site where the washerwomen will be able to rent the boots daily.

To make sure that the system can be adapted to local needs, the project started with the gradual hiring of 250 boots per day, with the number set to increase based on the management’s bi-weekly review of processes and procedures. A soon-to-be-launched FCA OHS Committee will review the project’s setup and systems, providing technical input where appropriate. Seeing if and where this can be replicated, part of the FCA’s support will include targeting and providing diggers on the same mine site with applicable PPE before expanding to other mine sites.

Washers standing in line to rent wader boots. Many women report they are very eager to rent boots and look forward to the increased sense of dignity it gives to work with PPE, Kamilombe mine site April 2022.

How does it work?

At a daily rate of 1500 Congolese francs ($0.75), of which 500 ($0,25) is subsidised by the mining cooperative, interested washerwomen rent wader boots from the Kamilombe mine site daily. In addition, the women provide their mining cooperative membership card for a size card they can exchange at the next booth for the wader boots.

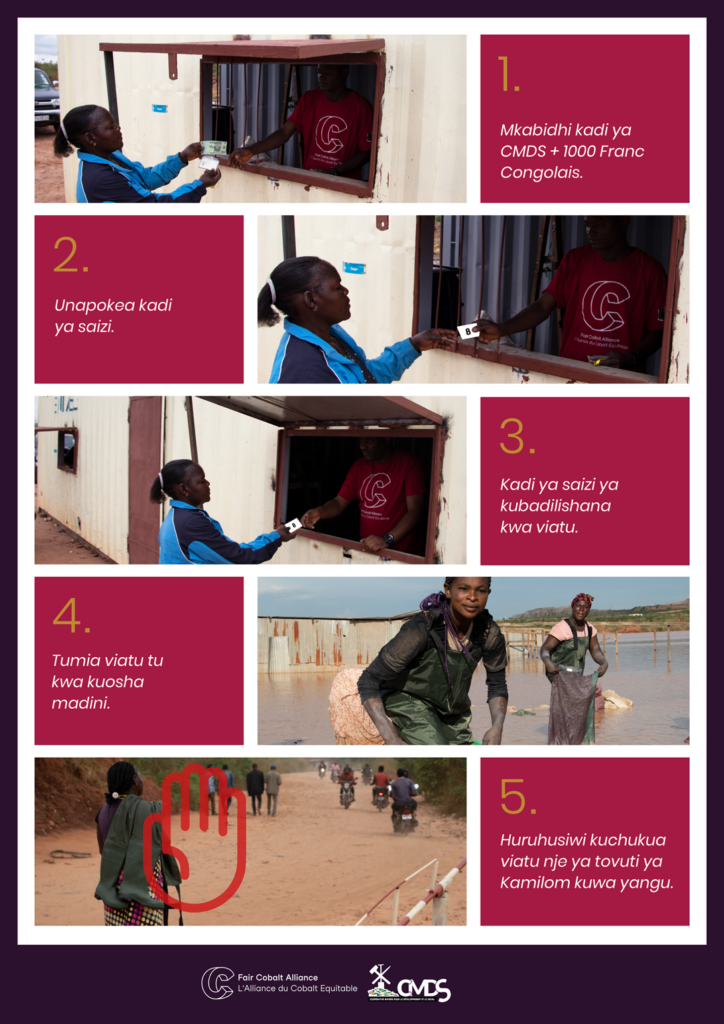

The boots are available for rent every day but must be returned no later than 6pm and their use is limited to washing minerals within the vicinity of the mine site. Before returning, the women have to wash the exterior of the boots at the washing station next to the renting store, wiping them dry before handing them over to the store team who will check for any damages and disinfect the interior before hanging them to dry. The washerwomen’s president explained the entire renting process during the ceremonial launching of the project, with instructions featured on a poster hanging in the renting store (see below).

Poster text translation:

1. Hand over CMDS card + 1000 Franc Congolais.

2. You receive a size card in exchange.

3. Exchange size card for boots.

4. Only use boots for washing minerals.

5. You are not allowed to take the boots outside the Kamilombe mine sit

Both feet in the water: project governance and maintenance

Initially funded by FCA, the project is attempting to develop a revolving fund: using the daily rental fee that is saved to either replace written-off boots, increase the stock of boots available, enable maintenance support of the renting store, or invest in alternative PPE like gloves. A PPE steering committee and washerwomen committee was set up to govern the PPE project and to establish a set representation of the washerwomen. The washerwomen committee was set up to provide input from their perspective and ensure local ownership.

The PPE steering committee comprises one member of CMDS, one from the FCA, and one from the washerwomen committee. This committee is to review all procedures and processes involved in the rollout of the equipment, including the renting procedure, replacement procedure, inventory checking, and the financial management of the project. The PPE committee will have bi-weekly meetings at the beginning of the project, which will later graduate into monthly sessions. The FCA OHS committee, consisting of external members with OHS expertise, will provide input into the project.

A washerwoman washing her rented boots at the end of the day before handing over to the store for safekeeping. As the boots are rented out on a daily basis, proper cleaning and sanitasing is prioritised to maintain the boots’ condition and prevent the spread of infections.

Rinse, wash, repeat – developing replicable solutions to tackle OHS hazards experienced by women miners washing cobalt ore

After full execution of the project, mining cooperative CMDS plans to make use of the boots obligatory, an attempt to establish a precedent for safe working conditions. The improved working conditions and increased sense of dignity have expedited the necessity to invest in more on-the-ground improvements. Pending additional financing, we are – together with CMDS – exploring ways further to introduce more PPE to the Kamilombe mine site.

While the initiative was welcomed, we are yet to find the best model to optimize its potential. Our team is actively collecting feedback on how to make the system fit for purpose, as concerns around hygiene and ownership have already come up. Our vision is to expand the provision to other mine sites, which is why the FCA insists on scalable, replicable interventions: economic models that ensure local ownership of these processes.

To demonstrate the necessity of such interventions, when asked about the project, Virginie Kalumbu, one of the lavages commented, “This project is a very good thing for us because before we suffered a lot from different diseases from working in bad conditions. The water in which we work is not good, it is polluted.”

Her colleague, Josephine Kalamba, added, “We are now saved, we were always sick because of the dirty water in which we work and I was spending a lot of money to be treated. For me this project has come to get us out of this daily suffering.”

This video clip shows the ceremonial launching of the PPE project at the Kamilombe mine site on April 18th, 2022. Together with CMDS and the president of the washerwomen, FCA introduced boots to the washerwomen. Local theatre group SKM performed sketches and songs, highlighting the importance of PPE and safety conditions. A local studio produced the video clip.